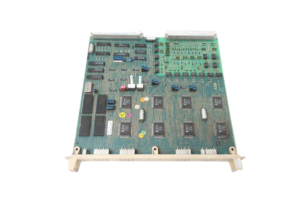

BENTLY 3500/94M 184826-01

The Importance of BENTLY 3500/94M 184826-01 in Industrial Automation

In the realm of industrial automation, the BENTLY 3500/94M 184826-01 stands out as an essential component, particularly within the electrical engineering landscape. PGC5000 is a leading platform for industrial automation components, and this device is a testament to the advancements in technology that drive modern industrial processes.

The Role of Electrical Engineering in Industrial Automation

Electrical engineering plays a pivotal role in shaping the efficiency and reliability of industrial automation systems. As industries evolve, the demand for precise control, monitoring, and data analysis has surged. The BENTLY 3500/94M 184826-01 is designed to meet these needs, providing engineers with a robust platform for monitoring machine health and performance.

Technical Specifications: IEC60947-2 Compliance

The BENTLY 3500/94M 184826-01 is engineered with a variety of technical specifications that adhere to IEC60947-2 standards, which are crucial for industrial equipment. Some of the noteworthy specifications include:

- Voltage Rating: The device supports various voltage levels, ensuring compatibility with different systems.

- Current Rating: Designed to handle significant load currents, the BENTLY 3500/94M is reliable under various operational conditions.

- Protection Class: With a high IP rating, the unit guarantees protection against dust and moisture, which is critical for industrial environments.

- Operational Temperature Range: The device can operate in extreme temperatures, making it suitable for diverse applications.

- Communication Protocols: Supports multiple protocols for easy integration with existing automation systems.

Applications in Industrial Automation

The versatility of the BENTLY 3500/94M 184826-01 makes it applicable across various sectors within industrial automation. Some of the key applications include:

- Condition Monitoring: The device is instrumental in real-time monitoring of machinery, allowing for predictive maintenance and minimizing downtime.

- Data Acquisition: It collects and analyzes data from various sensors, providing insights that help optimize performance and efficiency.

- Control Systems: The BENTLY 3500/94M serves as a critical component in control systems, ensuring that machinery operates within safe parameters.

Renewable Energy Applications

As the push for renewable energy sources intensifies, the BENTLY 3500/94M 184826-01 plays a significant role in the monitoring and control of renewable energy systems, such as wind and solar power installations. By ensuring optimal performance through continuous monitoring, this device helps reduce operational costs and increase energy efficiency.

Conclusion

The BENTLY 3500/94M 184826-01 is more than just a component; it is a critical asset in the ever-evolving field of industrial automation. Its adherence to IEC60947-2 standards and its diverse applications in both traditional industrial settings and renewable energy sectors underscore its importance. For more information on industrial automation components, visit ABB Part Supply or check out the International Electrotechnical Commission (IEC) for standards and compliance guidelines.